Home > News & Blog > Programming-as-a-Service

In EPS we offer Programming-as-a-service

What does this mean?

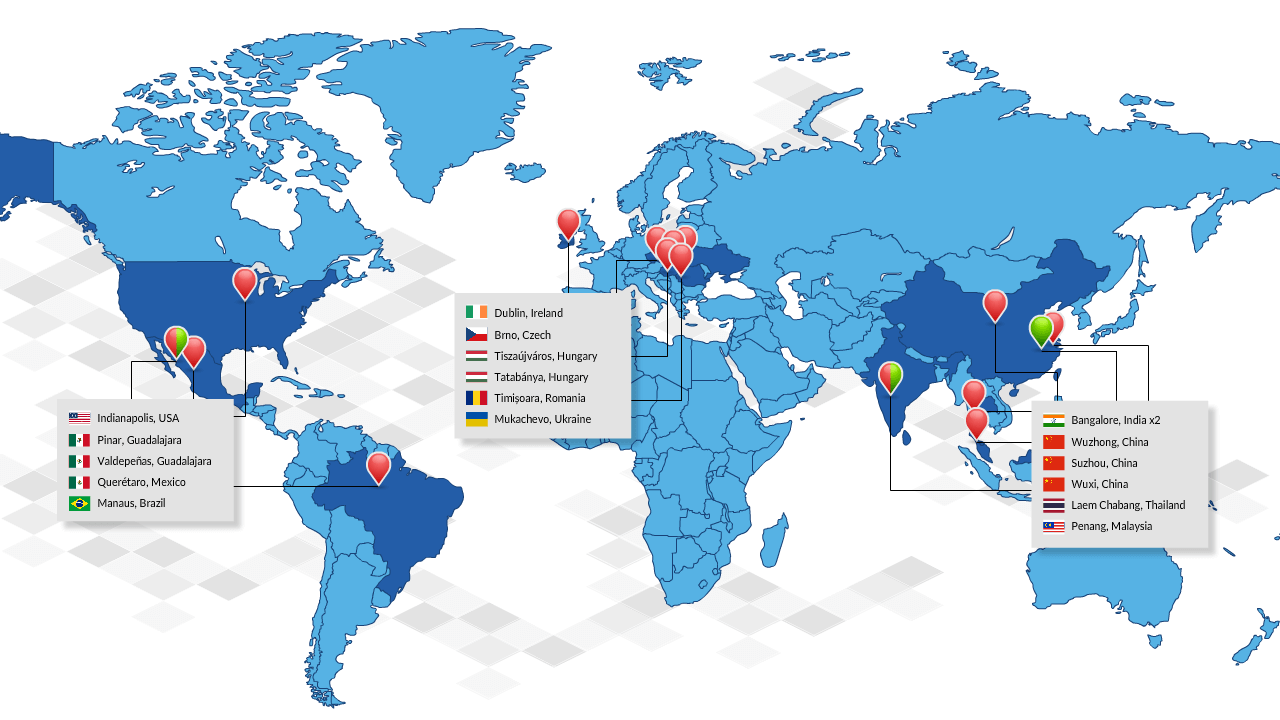

It means we take our genuinely global network and provide volume, quality Programming-as-a-Service on any device anywhere in the world.

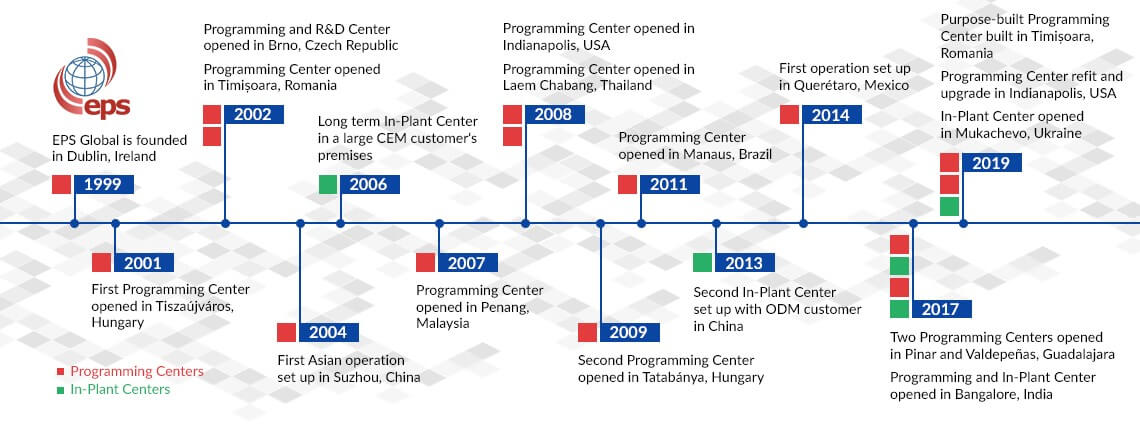

If it sounds simple, it’s not. We have 20 years invested in growing our network and our quality system from the ground up in 12 countries around the world.

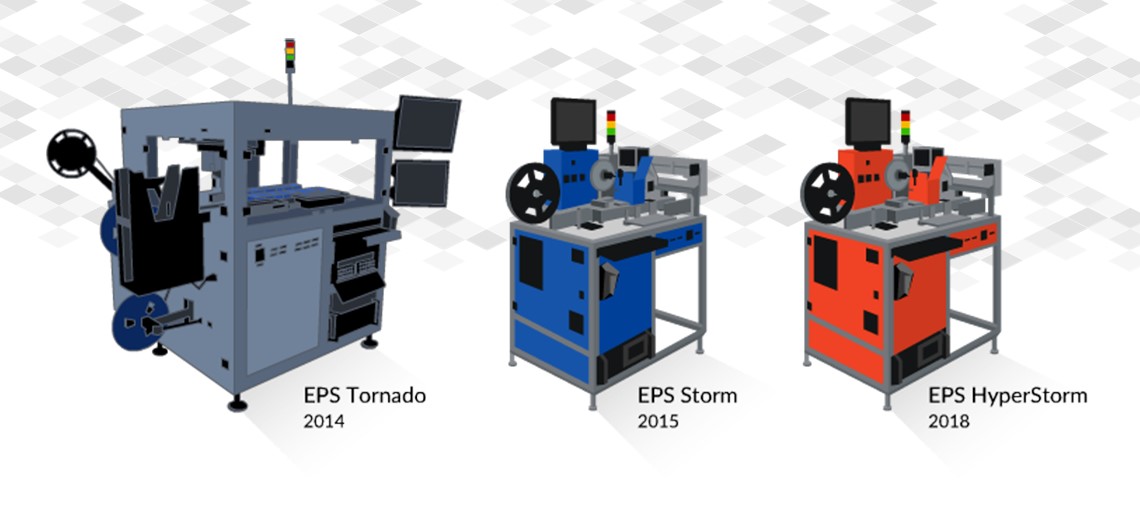

All our locations are equipped with our automated handlers, designed and manufactured by EPS, which are now in their 6th generation of system design.

There has been a lot of learning along the way.

After 20 years in the industry looking at the development of programming, and the evolution of the decision-making process for programming procurement by our customers, I have concluded there remains a sustainable advantage in our global programming-as-a-service model.

ESCALATING PROGRAMMING TIMES & EQUIPMENT COSTS

Apart from Programming-as-a-Service, there are essentially 2 alternatives:

1. PROGRAM AT IN CIRCUIT TEST (ICT):

Programming at ICT is essentially free if the programming time is insignificantly small as compared to the test time. If the programming time is significant however, the entire throughput of manufacturing is affected. As there is $2M – $10M per line of capital equipment invested in most SMT production, any slowdown of line rates means this technique quickly becomes disproportionately expensive.

One of the big issues as memories and processors have become larger and faster is designing Input / Output (IO) that can keep pace. The architectural challenge is now being reduced to getting data to the pins. Locating and routing physical pins on higher capacity but physically smaller devices is a huge challenge. The net of this issue is that absolute programming times are increasing on many devices. This is set to continue with new memory technologies such as eMMC and UFS taking significantly longer to program than their predecessors. The unseen aspect of this issue though is that even small devices such as microcontrollers are affected. The need to reduce package size reduces pin count and means even memories in the kilobit range can take time to program on resource and space constrained chips.

2. BUY YOUR OWN EQUIPMENT

In general, there is a network of reputable and established automated programming equipment makers based in the US, Japan and Taiwan. These companies make reliable but expensive equipment and service global customer networks via distribution and a global field service network. There are 4 main challenges for customers in this scenario:

- Cost is a key factor, high-performance machines from these vendors can cost in the region of $200 – $600K depending on functionality. This adds to investment and payback cycles for customers, increasing the overall risk.

- Even with top of the range equipment, reliability and service is a factor that varies with your location in the world. All automated handlers are complex mechatronic systems that break down from time to time. Companies with extensive service networks in the US and Europe may sometimes have more variable service offerings in China or India. Key to the viability of this option is to develop a real understanding of what can go wrong with a programmer and how long in days specific problems take to fix. All of this field service is charged for and must be factored into any decision.

- Another challenge is the mobility of projects globally. A customer business case to buy equipment based on two projects in-house can be invalidated if one project moves geographically, and multiple machines need to be procured.

- Staff costs also need to be considered, with each machine requiring operations and technical staff for set up, operation and maintenance.

THE SOLUTION

EPS Global has considered these challenges in developing our service offering. In addition, we can offer the cost and technology advantages of the specialist. So, what does this mean for the customer?

- It means predictable, competitive per unit costs, often without NRE. It means the ability to flex costs to volume and to move capacity globally as projects move.

- It means reliable capacity with multiple machines per location and a large in-house support team, EPS are never dependant on the reliability of a single machine at any one time.

- It means being able to support the latest chip technologies without further investment and staying ahead of innovation in areas like security.

Key to these benefits however is our proximity to the customer. When looking at a decision to outsource programming-as-a-service, no customer anywhere in the world will need to travel far to find an EPS Service Point. This allows them to combine the benefits of in-house and outsourced solutions with none of the downsides.

A HYBRID MODEL

Many of our newest customers are already investors in their own programming capacity and have experience in the issues highlighted here. With these customers we often suggest a hybrid model. This model means they use their existing in-house equipment on older more stable production runs. This allows them to maximise utilization and get longer useful lifetime out of their equipment. They then use EPS’s service on new technology or capacity upsides.

OPERATIONAL BENEFITS

EPS’s focus in Operations is on 3 areas:

1. COST

- We develop and maintain our own handling systems.

- We operate in low cost areas globally.

- We manage our global capital base to maximize efficiency. Equipment performance is monitored online, and machines are frequently repositioned to a goal of >90% utilization.

2. QUALITY

- Our Quality system is developed over 20 years in the business. It is specific to programming as our speciality.

- Our system is Globally homogeneous and an Internal Audit Function monitors compliance and improvement.

- Our most demanding customers have worked with us over time to develop what is now a best-in-class system.

3. INNOVATION

- We develop 2 platforms tailored to specific device families, optimizing the type of handlers used in each customer application. This gives us large capital efficiency over companies buying 3rd party machines.

- We blend the best of acquired knowledge from partners with internal expertise to develop our offering.

- We are at the forefront of new developments in the industry such as secure provisioning.

A SELECTION OF EPS-DESIGNED AND MANUFACTURED AUTOMATIC HANDLERS

In short, programmable devices are proliferating, and sourcing programming can be challenging. EPS’s programming-as-a-service is a best in class solution that solves many of the difficulties facing customers.

We are always looking to expand our partnerships and service offering. If you would like us to research and quote on any project, please contact us today.

Glossary of Terms